In any industrial setting—whether it’s a bustling food plant, a busy warehouse, or a remote offshore rig—safety isn’t just a guideline; it’s the bedrock of operations. One of the most persistent and overlooked hazards, however, is literally right under our feet: slippery floors. Slips, trips, and falls are among the most common causes of workplace injuries, yet many companies still rely on temporary solutions that don’t last.

Enter AMCO Anti-Slip Systems, a fully engineered solution designed to turn high-risk surfaces into secure footing, minimize accidents, and improve operational efficiency.

The Scale of the Problem

To understand why floor safety is so crucial, consider this number: 10,650. That’s the total number of accidents caused by slips, trips, and falls reported in Thailand in a single year. Each of those numbers represents a real person, a real family affected, and a loss in productivity that ripples through the entire organization.

For safety managers and plant operators, this raises a tough—but essential—question: Are the measures in place actually making things safer? Or could they be creating new risks?

Quick Fixes Often Fail

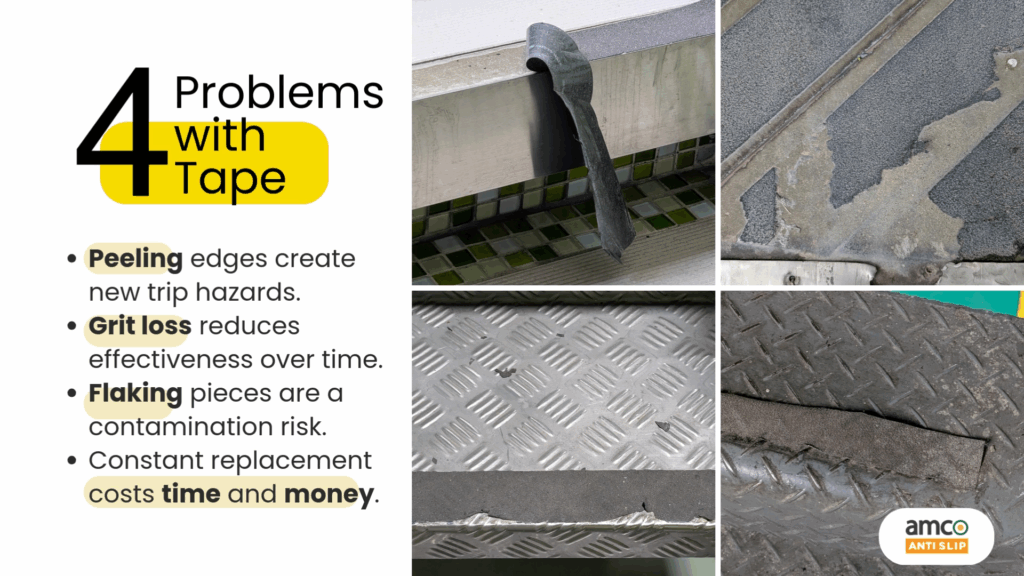

Many industrial facilities try to address slippery surfaces with quick solutions like anti-slip tape. At first glance, tape seems cheap, convenient, and easy to install. But the reality is far from ideal:

- Edges Peel Up: Exposed edges can create new trip hazards.

- Grit Wears Down: High-traffic areas quickly become smooth and ineffective.

- Contamination Risks: In food or pharmaceutical plants, flaking particles may compromise hygiene.

The result? Constant replacement cycles that cost time, money, and frustration—and still don’t solve the underlying safety problem.

AMCO Anti-Slip: Engineered to Last

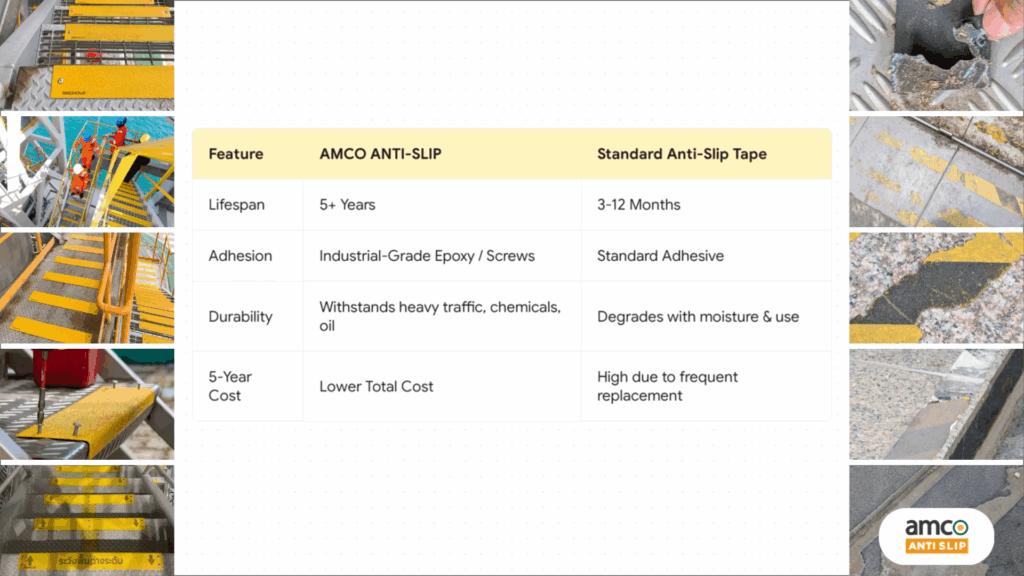

Unlike tape, AMCO installations are designed for durability and long-term reliability. While tape may last a year at best, AMCO solutions can last five years or more.

The secret? Industrial-strength bonding. AMCO anti-slip plates are either mechanically fastened or bonded with high-performance epoxy, ensuring that moisture, wear, or heavy traffic won’t compromise their grip.

Upfront costs may be higher than temporary fixes, but when you consider the total cost over five years, including labor, downtime, and replacement, AMCO is the clear winner.

A System, Not Just a Product

AMCO Anti-Slip isn’t a one-size-fits-all product—it’s a comprehensive system designed for every high-risk area.

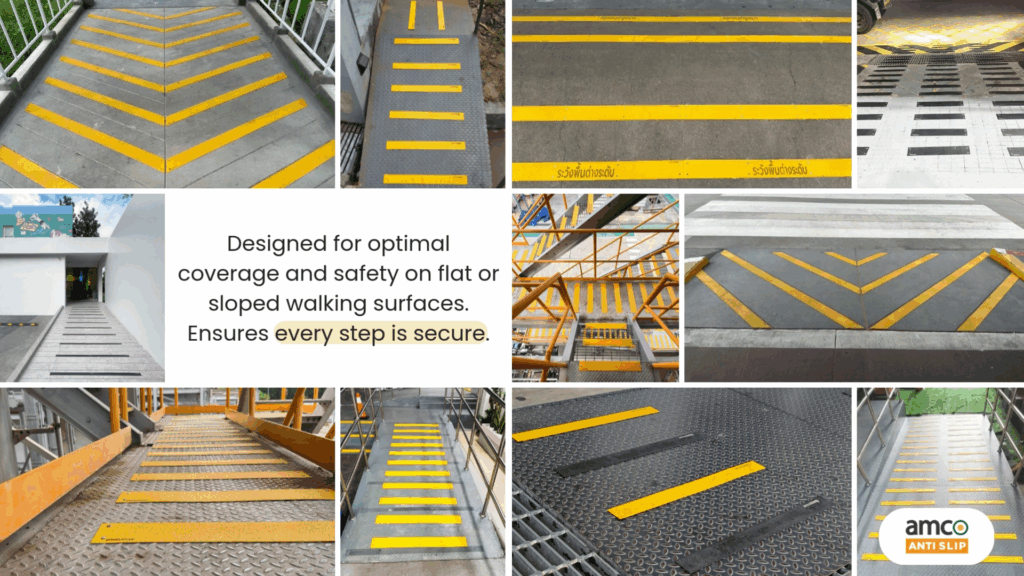

Walkway Surfaces

Walkways are the backbone of any industrial facility. AMCO walkway plates provide wide, consistent coverage across main floors, ramps, and catwalks, giving every step a secure grip.

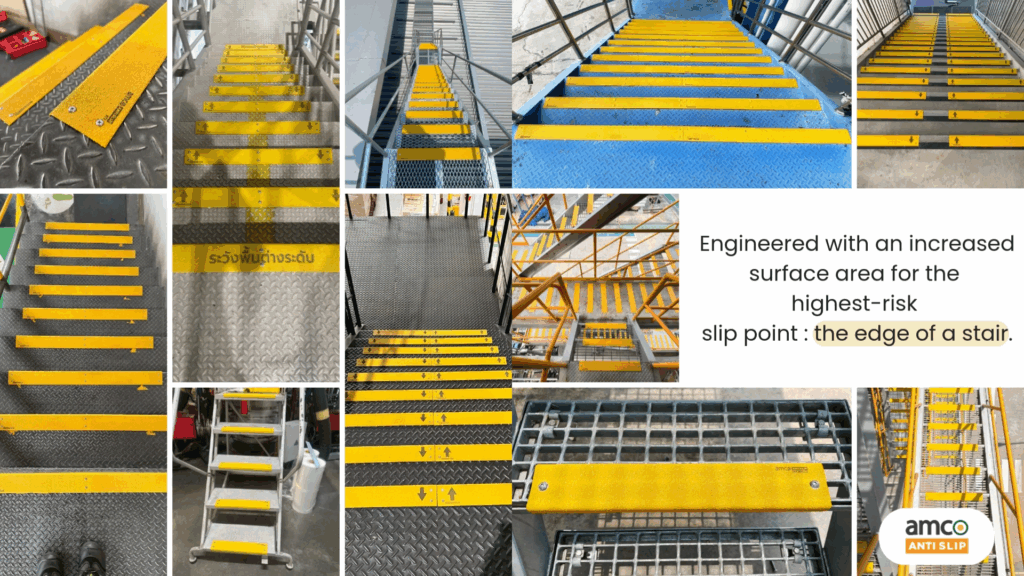

Stair Nosing

Stair edges are a frequent site of accidents. AMCO stair nosings wrap over the step’s edge, increasing surface contact and traction where it matters most.

Ladder Surfaces

Vertical ladders are high-risk zones. AMCO ladder solutions provide extra grip for boots and hands, reducing the chance of dangerous falls.

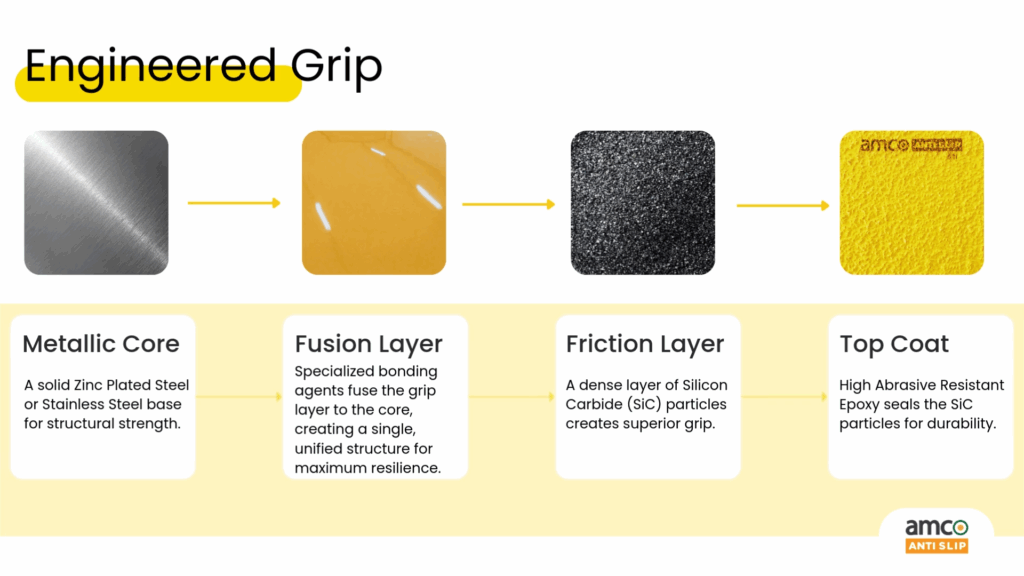

The Engineering Behind the Grip

AMCO’s performance isn’t accidental—it’s the result of multi-layer engineering:

- Solid Metal Core: Zinc-plated or stainless steel for strength and durability.

- Specialized Bonding Agents: Fuse the layers into a single, resilient structure.

- Silicon Carbide Layer: Creates exceptional grip under boots, even in wet or oily conditions.

- Epoxy Top Coat: Locks particles in place and ensures long-lasting performance.

This isn’t just a coating—it’s a composite safety solution engineered to last.

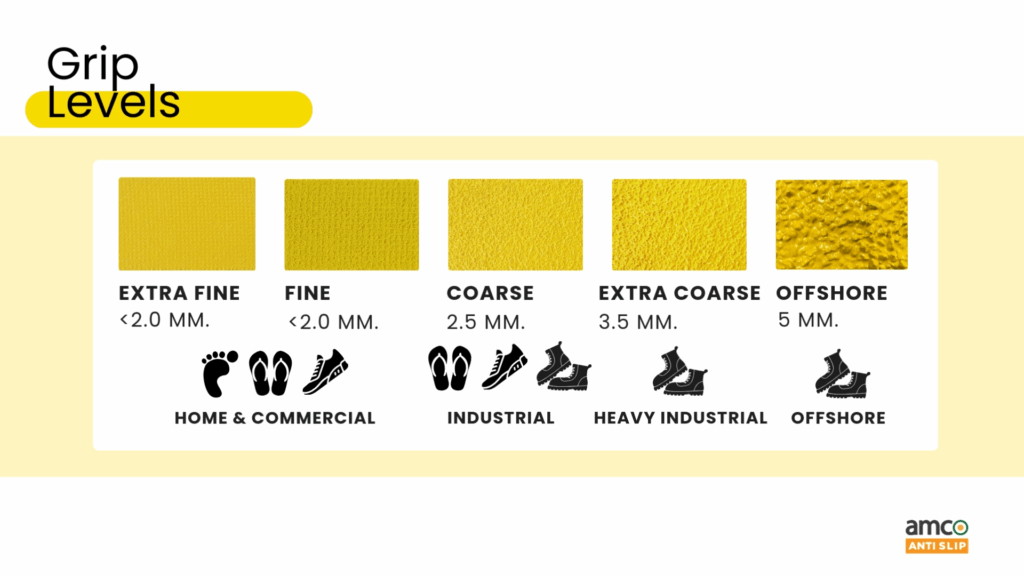

Customization for Every Environment

No two industrial sites are identical, which is why AMCO is fully customizable:

- Material Selection: Zinc-plated steel for general use; stainless steel 304/316 for food plants or offshore rigs exposed to corrosive environments.

- Grip Levels: Coarse for standard floors, extra coarse for high-wear areas, offshore-grade for oil, grease, and grime.

- Sizes and Shapes: Custom designs to fit unique equipment layouts or floor geometry.

- Visual Options: Standard safety yellow, black, warning stripes, or custom text for clear communication.

This level of customization ensures that AMCO becomes integrated into the facility’s safety DNA, not just an afterthought.

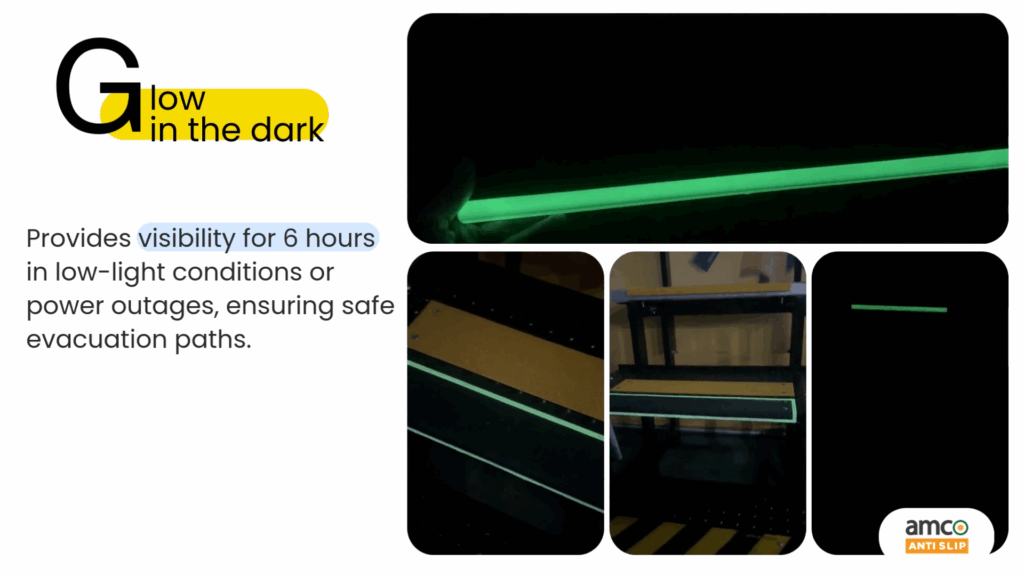

Advanced Safety Features

Modern industrial safety isn’t just about preventing slips—it’s about preparing for worst-case scenarios:

- Glow-in-the-Dark Strips: Stay visible for up to six hours in power outages or smoke-filled environments, guiding people to safety.

- Antibacterial Coating: Tested to ISO standards, reducing harmful bacteria like E. coli and Staphylococcus aureus by up to 99.99%. This is particularly critical in food and pharmaceutical facilities.

These features provide peace of mind, knowing the floor itself actively contributes to safety and hygiene.

Installation Made Simple

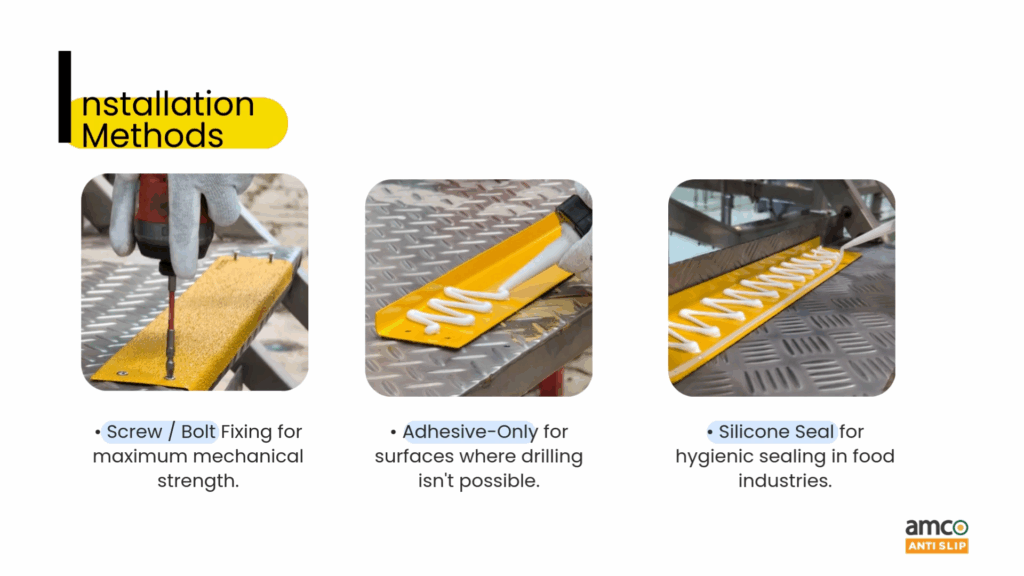

AMCO is engineered not only for performance but also ease of installation:

- Mechanical Fastening: Bolts or screws for maximum strength on steel or heavy-duty surfaces.

- Industrial Adhesive: Ideal for concrete, tiles, or surfaces where drilling isn’t possible.

- Sealed Edges: For food-grade areas, preventing water or bacteria from collecting underneath.

This flexibility ensures that AMCO solutions can be applied anywhere and remain effective for years.

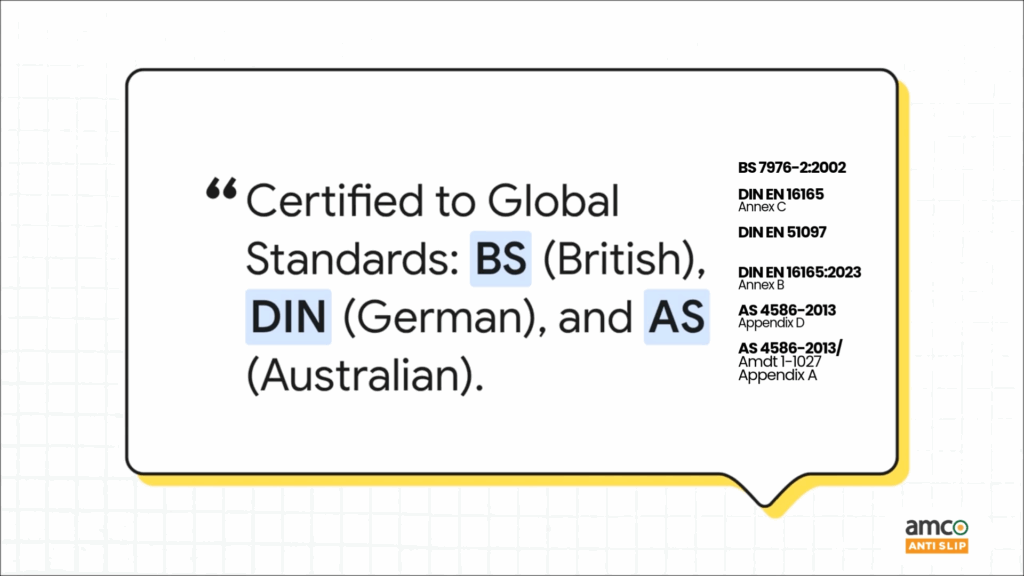

Certified and Tested

AMCO’s claims aren’t just marketing—they’re independently verified. Performance meets British, German, and Australian safety standards, providing confidence that the system works exactly as advertised.

Real-World Impact

Consider the true cost of a workplace accident:

- Lost work hours and productivity

- Insurance claims and legal costs

- Potential long-term injury or permanent disability

- Emotional and social impact on employees and families

When weighed against a one-time investment in AMCO, the decision is obvious. Safety isn’t just compliance—it’s one of the smartest investments a company can make.

Case Study: Factory Upgrade

A food processing plant in Bangkok had recurring slip accidents despite using anti-slip tape. After installing AMCO anti-slip walkways and stair nosings:

- Slip incidents dropped to zero within the first year

- Maintenance time for floors was reduced by 75%

- Employees reported feeling safer and more confident navigating work areas

This example highlights how engineering, durability, and customization combine to prevent accidents and boost operational efficiency.

Conclusion

Floor safety is often overlooked until an accident happens—but the impact is real and costly. AMCO Anti-Slip Systems provide a permanent, engineered solution that lasts, performs, and integrates seamlessly into industrial facilities.

From multi-layer construction to custom grip options, from glow-in-the-dark and antibacterial features to independent safety certifications, AMCO is more than a product—it’s a complete safety system.

Investing in safety isn’t an expense. It’s a strategic decision that protects your people, your operations, and your bottom line.

Tags :

Categories :

Other Posts :

- Sand Filter vs. Alfawater: Which Water Filtration Technology Can Truly Cut Industrial Costs?

- 5 Surprising Ways This New Tech “APEF” Uses Physics to Revolutionize Water Treatment

- More Than amco ANTI SLIP: Why amco+ Antibacterial are the New Standard for Factory Safety

- Glow-in-the-Dark “amco ANTI SLIP” Safety for Emergencies

- “amco ANTI-SLIP” Solutions: Engineered Safety for Industrial Floors, Stairs & Ladders